Non-contact

thickness gauging of

uncured powder coatings

Based on airborne ultrasonic

- Measurement range (cured coating) from 30 to 105 μm

- Gauging instantly during or after spraying before the oven

- in 30 seconds unwrapped, referenced and got first reading!

- Easy use

- One setting, independent of colour, powder and carrier

- Works well on curved surfaces and tight radii

- USB connector for data transfer and firmware update

- Thousandfold successfully proved in practice

Simple and flexible

Easy handling and high flexibility

SaveCoat 7 is impressive easy in handling and fast in use. After a simple zeroing on the reference block (acquisition of the reference signal) the gauges can measure powder coatings on all as metallics, MDF, Wood, Glas and plastics independently of colour, powder brand and coating technique (tribo or corona).

The first reading within 30 seconds…

Taking out of the carrier case, switchin on, refrencing and proceed on your product…after 30 seconds you have the first thickness reading. Photothermal systems are from physical reasons much more demanding and time consuming in preparation and use. Their calibration and adjustment depends on colour, carrier and powder type. In adition the physical interaction is slower which is a handicap in line at moving and/or oscillating parts.

Works on curved surface

A narrow sound beam in the measuring distance as well as the laser based Guiding and Targeting System (LGTS) allows SaveCoat 7 to easely measure on strongly curved surfaces. The successful long time use at bicycle manufactures tell stories.

Economical and ecological forceful

The consequent use of the non-contact powder gauge SaveCoat 7 avoids rework and saves a two-digits percentage of powder. Under realistic scenarios at smaller and medium powder shops the use of the gauging technology results in an interesting economical benefit. This benefit is accompanied by a substantiel ecological advantage – to get more out of less and simultaniously protecting the environment.

From the ecological point of view the SaveCoat is a remarkable valuable quality assurance system. Assumed at a typical powder line the systematic use of the powder gauging is saving 10% of powder consumption ( reduced overcoating) and prevents a smaller damage case (rework) an ecological CO2 payback of 1 month results. In other words: The extra outlay for the gauge and the related measurement work is compensated after one month!

| Annual powder consumption | 2 to | 5 to | 10 to | 100 to |

|---|---|---|---|---|

| Saving potential 15% | 0.3 to | 0.75 to | 1.5 to | 15 to |

| Average powder price* | 10 € | 10 € | 10 € | 10 € |

| Savings / Cost reduction per month | 250 € | 625 € | 1’250 € | 12’500 € |

| Savings / Cost reduction per year | 3’000 € | 7‘500 € | 15’000 € | 150’000 € |

| Amortization SC7 | 26 Mte | 11 Mte | 6 Mte | 3 Wo |

*These examples are based on average rates, which can vary according to the type of powder and the purchased quantity.

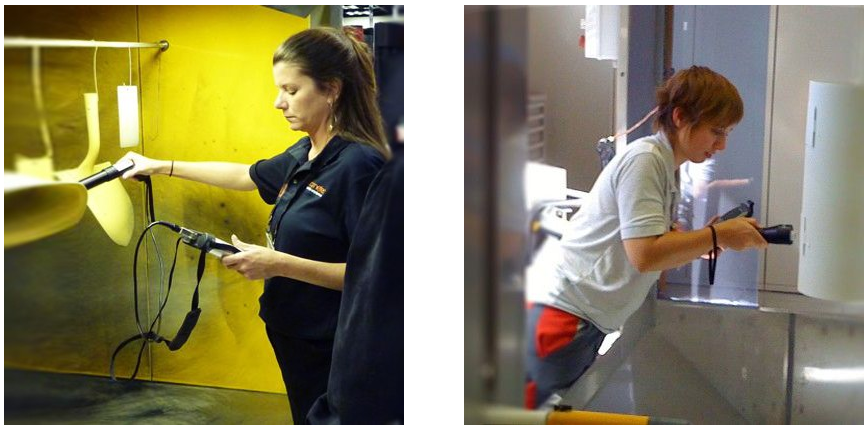

Ergonomical Design

The ergonomical design of SaveCoat 7 makes sure that even at the end of your shift you can coat and measure without pain in your back. A picture says more tha a thousend words …

Measuring Technique

- contactless using airborne ultrasonics

- Resolution: 1 μm

- measurement range: 30 – 105 μm

- Accuracy: +/- 5 μm

Specs SaveCoat 7 Unit

- datamemory: flash for 200 readings

- battery: 7.2 V NiMh, rechargeable

- runtime full charge: typically 7h in steady use

- charging time about 1.5 h

- power supply: 110-230 V, 50 – 60 Hz

- casing: aluminium, IP54; 115mmx185 mmx 35 mm

- graphical user interface with menustructure

- Selectable language: german, english, spanish, french and dutch

- USB interface for updates and data transfe

Powder coaters want miss the Powder Gauge again

The users of SaveCoat 7 have learnt how easely and fast they can get reliable measurements of the final powder coating thickness right at the powder station before curing in the oven. Without a fear surcharge the result is a rework free process. The responsible of a bigger powder shop (> 150 tons of anual powder consumption) once expressed it like this: “The gauge SaveCoat 7 regularely and systematically used and was a clever investment. If a unit is out for new calibration or repair the coaters ask twice a day if the gauge isn’t returned yet. Such a situation is very uncommon – nevertheless we will put an extra unit at our disposal!”